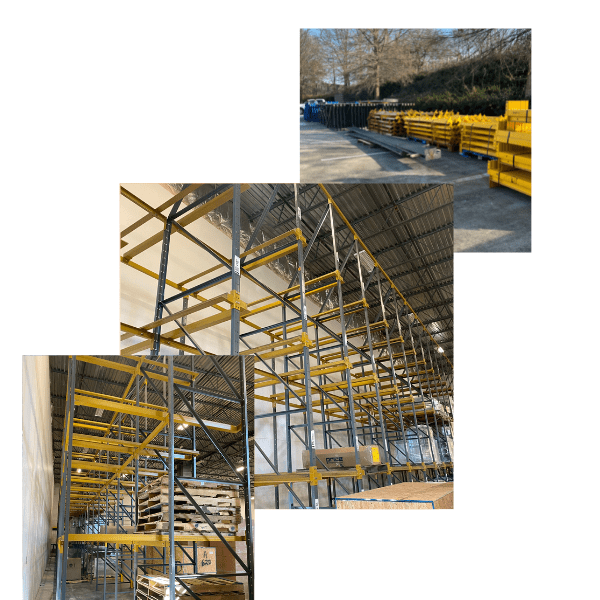

Drive-in racks are low-cost, high-density storage system that lets you stack pallets more than one deep, which means you need less space for aisles. Drive-in rack systems are often used against a wall.

Menu

Menu

- Home

- Services

- We Buy Equipment

- Contact Us