Applications and Advantages of Cantilever Racks

When it comes to warehouse storage systems, all shapes and sizes are required. Discover the advantages and uses of heavy duty cantilever racks.

Did you know that in 2017, warehousing costs in the U.S. alone amounted to an overwhelming $148.7 billion? That represents a spike of 3.3% from the $143.7 billion costs the year before!

The reason for this boom? One is the fact that three-quarters of Americans have already made online purchases. There’s also the fact that Millennials make 60% of their purchases over the web. Considering that they’re America’s largest generation, that translates to a lot of purchases.

Now the question is, is your warehouse up to the ever-increasing warehousing demand? If it’s not using cantilever racks yet, then it may fall short in terms of storage capacity. Not only that, but also organization and safety.

What exactly are cantilever storage racks though? What are their applications and what makes them advantageous over traditional shelving units?

All these, we’ve covered in this post, so keep reading to learn about these space-saving units!

Information About Cantilever Racks

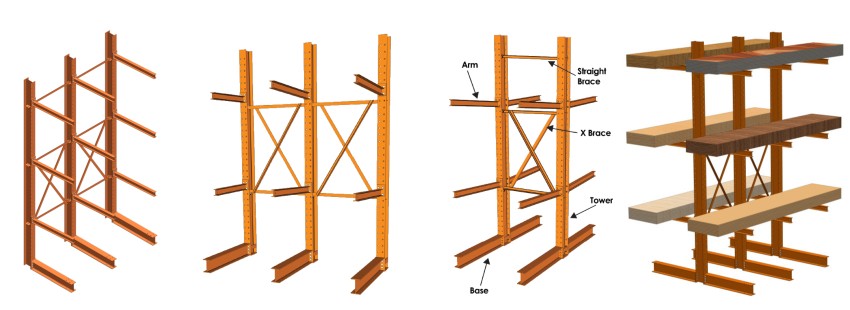

A cantilever rack is a free-standing, multi-level storage rack. Cantilever racks don’t have wire decks that you often find in pallet racking systems. Instead, they have horizontal arms connected to a vertical column.

This kind of set-up then eliminates column, vertical, or upright obstructions. It’s in this way that these deck-free rack systems allow for maximum use of storage space. You’ll find these racks in single- and double-sided systems.

You can use cantilever storage units for storing or displaying bulky, oversized items. They also work great for long objects that wouldn’t fit in other types of warehouse racks.

A Closer Look at the Structural Build of a Cantilever Rack Storage System

To better understand how a cantilever storage unit works, it’s best to know its components. Don’t worry though, as it’s not like pallet rack shelving units that can have over 10 parts. Cantilever racks usually only have four components.

Bases

The base anchors the entire rack system to the floor. It’s the main source of support for the tower (also called a column). The rack’s capacity and arm size dictate the size of the cantilever system’s base.

Towers

Next up, we have the towers, also called columns, verticals, or upright towers. These are columns located at the very back of the storage system. They are directly attached or mounted to the base for stability.

Tower stability is crucial, as it’s this part that provides support to the arms. Wobbly or shaky columns will fail to provide adequate support to the arms. This can then lead to load deflection, which can cause items to come toppling down from the arms.

Note that 26% of workplace injuries in the U.S. result from contact with objects and equipment. Such injuries can happen when an object from a rack falls and strikes a person. That’s one of the last things you want to happen to your people, so be sure your racks are stable!

Braces

Cantilever rack systems can either have horizontal (straight), diagonal, or crisscross (X) braces. Heavy-duty, high-density racks combine horizontal and X braces for optimal stabilization.

Each end of a straight brace connects to a column or tower. Whereas X braces go in the space between two straight braces (an upper and a lower brace). It’s in this way that an X brace reinforces the overall strength of the rack.

How long and wide these braces are should depend on the items the rack will carry or hold.

Arms

Finally, we have the arms, which are the parts that have direct contact with the product stored on the rack. Bolted straight on the tower, these arms are what hold and support the items you want to place on the rack. That’s why they are usually level with the brace, to ensure that they are stable and secure.

What Heavy Duty Cantilever Rack Systems are Often Used For

Now that you know what cantilever storage racks are, let’s talk about where you can use them. The possibilities are endless, but we’ll cite a few applications for starters.

Below are some of the materials that these racks can serve as a great display and storage solution for.

Building Materials

Cantilever racks make for excellent warehouse shelving for materials like lumber and drywall. These racks can also store poles, beams, and other long and odd-shaped materials.

Metal

Cantilever racks are also used as industrial shelving units for metal materials. These can be metal sheets like aluminum and steel, as well as bars, pipes, and tubing.

Materials Used in Furniture Making and Furniture Themselves

Furniture makers often deal with long and variable-sized materials. Think long planks of wood and metals like aluminum, steel, and wrought iron. Many also use plastic sheets and edging strips for their furniture.

These are items that cantilever storage racks can hold and secure in place. So long as you choose the proper cantilever build, you can be sure that the rack is strong and stable.

Carpeting

Cantilever racks are also ideal storage and display units for carpet rolls and rugs. Also, remember that the arms hold the load away from the floor. This then helps keep dust, dirt, and debris away from carpets’ and rugs’ sensitive fabric.

What Makes Cantilever Storage Racks Special

Cantilevers are your best option if you need unobstructed horizontal storage. Without vertical obstructions, you can maximize as much horizontal space as possible.

It also offers excellent use of vertical space, seeing as these racks don’t have decks. You do, however, have the option to install decks on them too.

High-quality cantilevers also come with vertically-adjustable arms. By adjusting these arms, you can fit more items on the rack with varying heights. The arms also come in different sizes capable of holding varying load capacities.

With cantilevers in your warehouse, you can say goodbye to floor-only storage. You can extend your storage from the floor to the space above and on the sides. Most importantly, it helps reduce the risks of accidents that fallen items on the floor can cause.

Invest in Cantilever Storage for Improved Warehouse Productivity

There you have it, all the applications, benefits, and advantages of cantilever racks. With these storage solutions, you can stock up more materials or display more items. This can then ultimately lead to improved productivity and higher profits.

Ready to start improving your warehouse, manufacturing facility, or shop’s bottom line? Then please feel free to request for a cantilever rack system quote now!